esa

electrostatic printing assist

Eklektika | A world novelty from Spengler Electronic AG

Electrostatic printing support for metallized printing substrates. A must in high-quality gravure printing in the packaging industry!

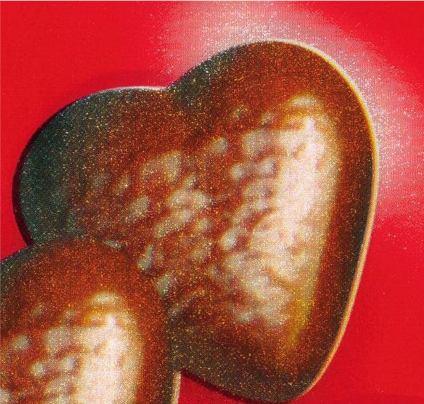

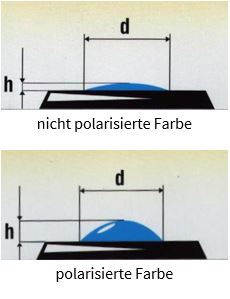

Eklektika was specially developed for gravure presses and guarantees “missing dot”-free quality printing on conductive, metallized printing substrates. The gravure ink in the engraving cups is polarized by the Eklektika ESA effect. The ink expands and improved ink transfer on the print substrate is ensured.

The Heliofurn-System is a non-contact electrostatic printing aid for avoiding so called “missing dots” during gravure printing. These “missing dots” are places in the print where ink from the ink cells of the gravure cylinder is not transferred to the web.

All systems comply with the latest ATEX explosion protection directives and can be used in hazardous areas.

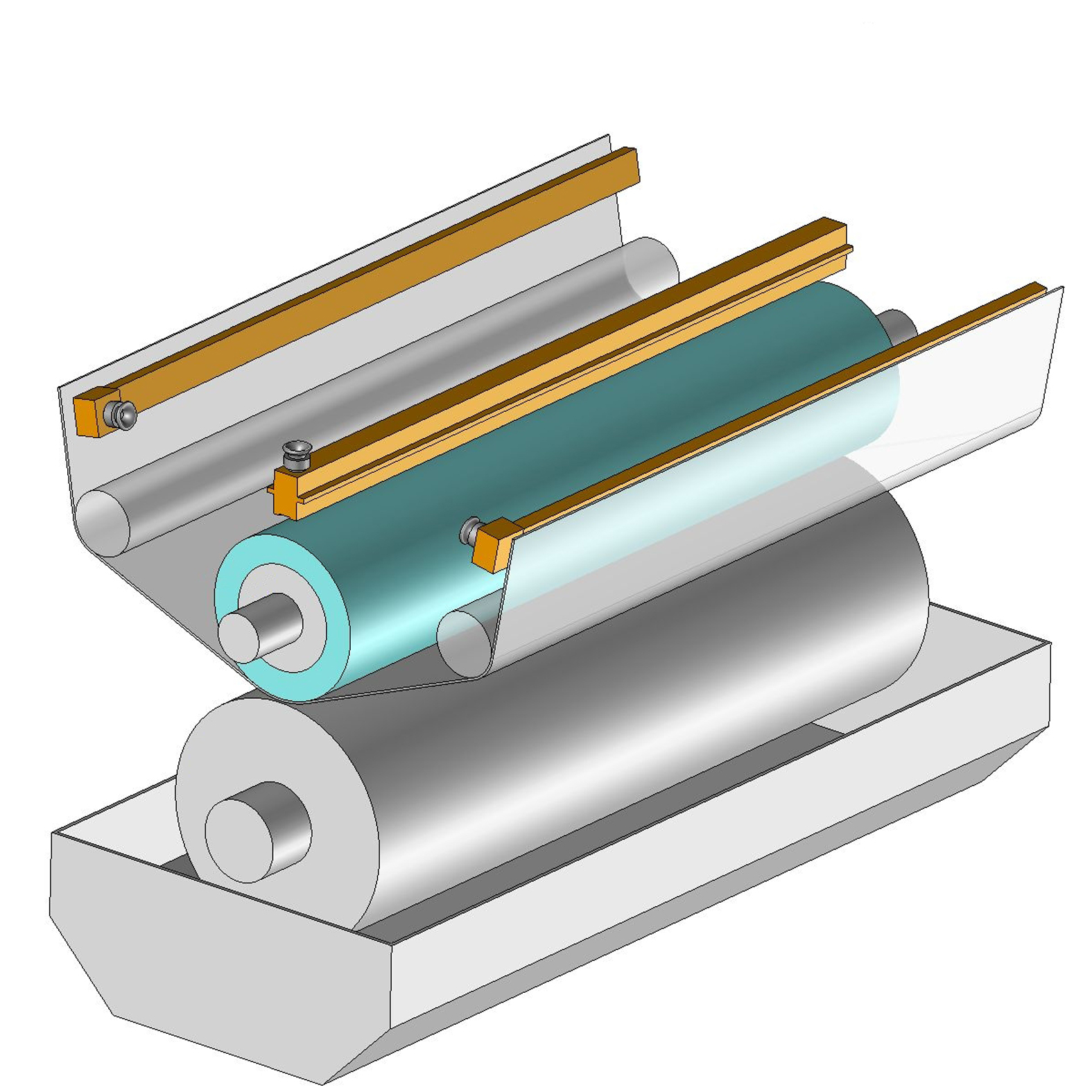

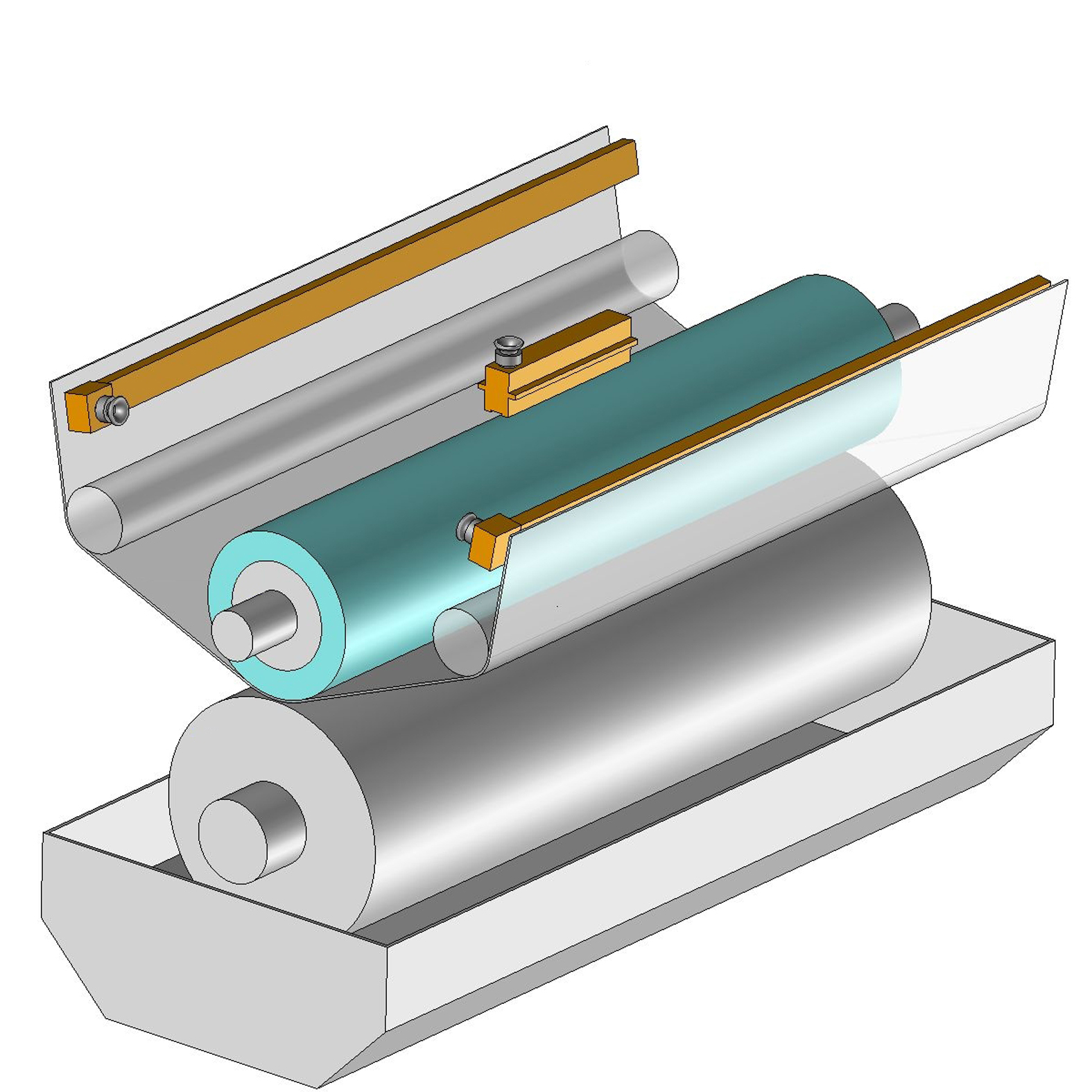

Indirect loading: 24 kV | The proven classic indirect loading system with a long or short electrode.

H-35 | Long Electrode

The proven classic indirect loading system with a long electrode. The working width of the electrode in nearly the length of the impression roller width. The charging device works with a 2 or 3-layer ESA impression roller.

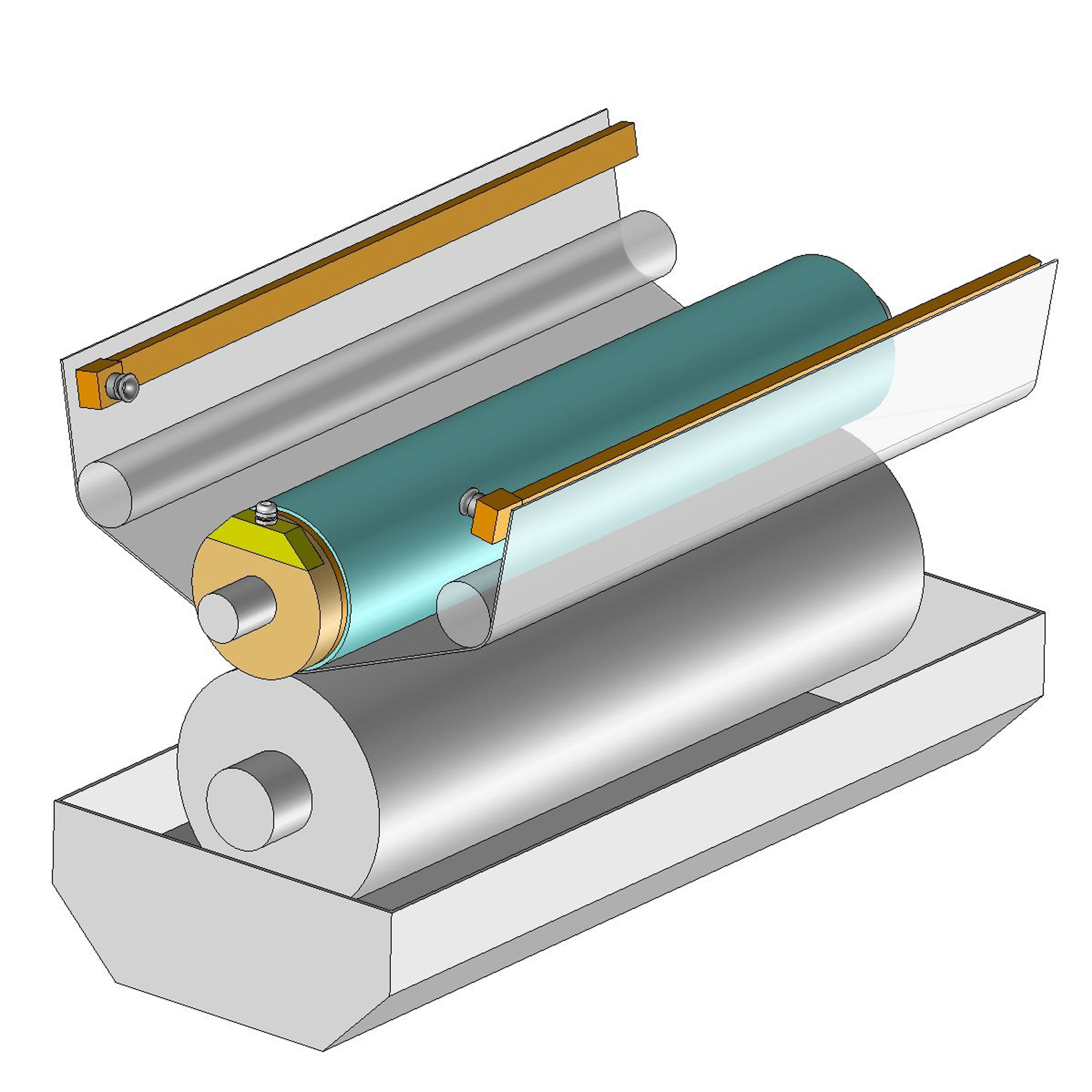

H-98 | Short Electrode

The indirect loading with the short electrode is almost maintenance-free. The working width of the electrode corresponds to 1/6 of the impression roller width. The charging device works with a 3-layer ESA impression roller.

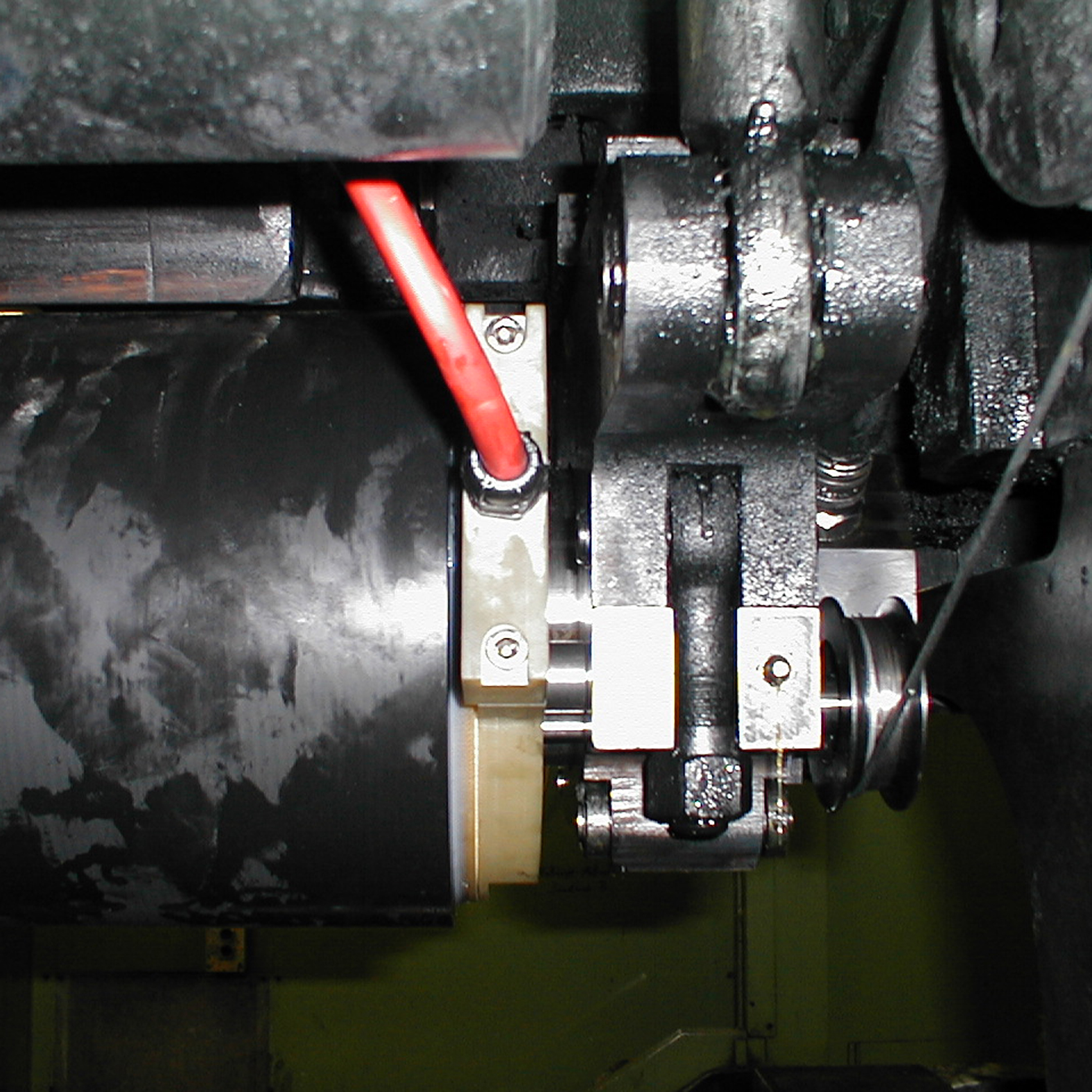

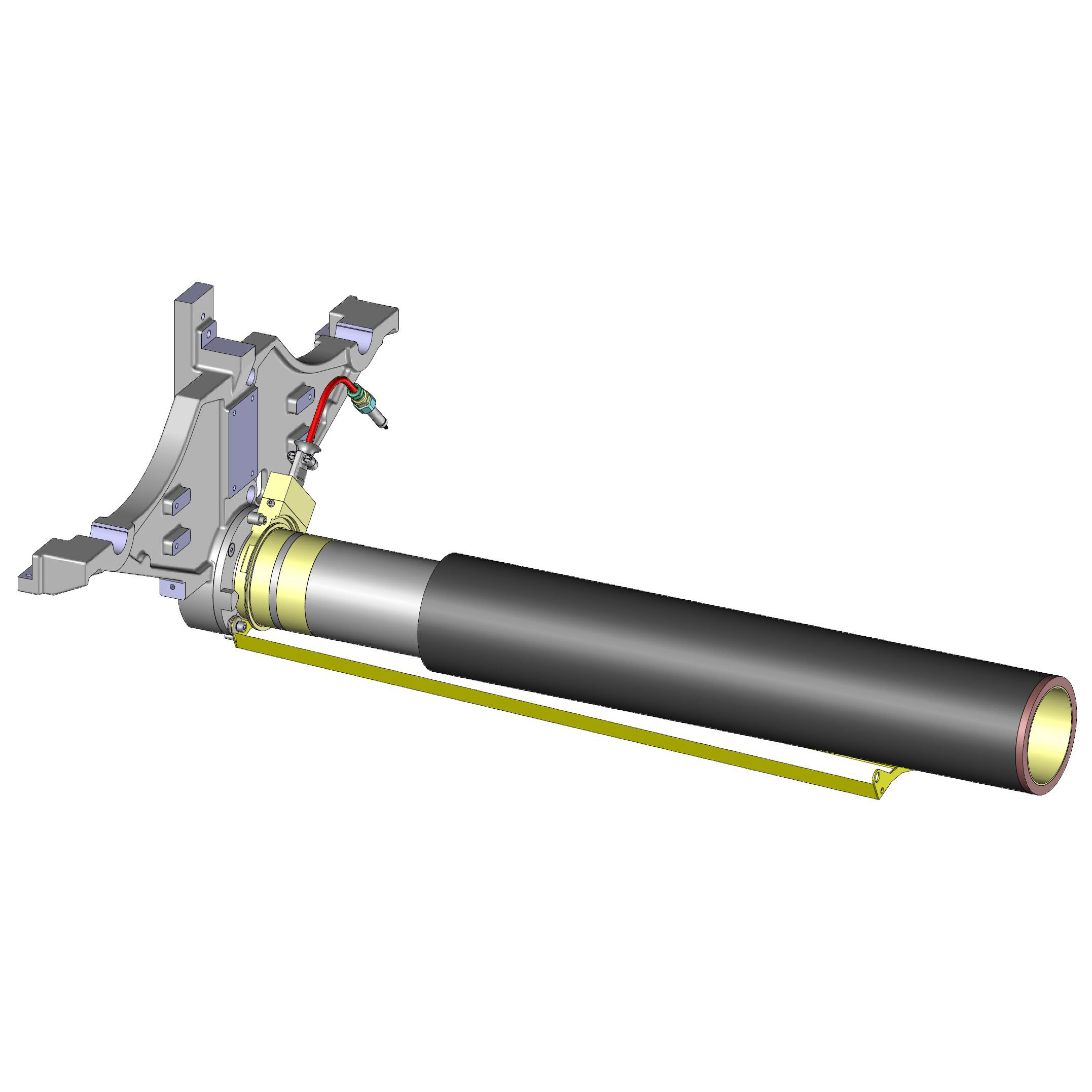

Direct charging: 3 kV | The maintenance-free direct loading systems for conventional impression rollers and impression roller sleeve systems.

H-2000 | Side Loading Device

Florentil | Side Loading Device for Sleeves

Head office

4105 Biel-Benken